Estimated chiller system Cost

Cooling Capacity

What's the water temperature range?

Preferred cooling method?

Power supply available?

Industrial Chiller Unit Types

MINNUO offers air-cooled, water-cooled, screw and low-temp chillers from 3KW to 10000KW.Factory direct • Export ready • Customizable • CE & ISO Certified

Industrial Chillers

Air-Cooled Chiller

Temp Range:

5°C - 30°C

Compressor:

Scroll/Screw Type

Refrigerant:

R134a

Refrigeration Range:

25KW - 7875KW

Applications:

Plastics, Laser, HVAC

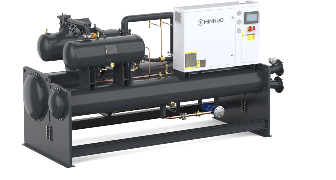

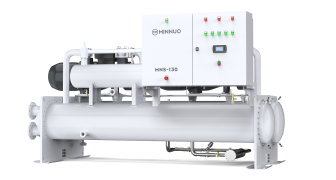

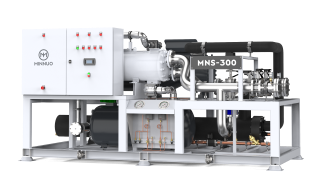

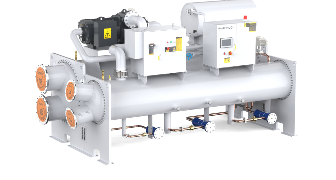

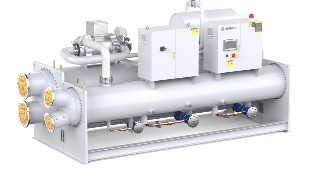

Water-Cooled Chiller

Temp Range:

5°C - 30°C

Water Tower:

Required

Refrigerant:

R134a

Refrigeration Range:

70KW - 10000KW

Applications:

Injection molding, Industry cooling

Low-Temperature Chiller

Temp Range:

-80°C - 0°C

Anti-freeze:

Protection included

Refrigerant:

R404A

Refrigeration Range:

55KW - 2439KW

Applications:

Electroplating, Pharma, Chemical

High-precision chiller units

Temp Range:

5°C - 50°C

Compressor:

Scroll/Screw Type

Refrigerant:

R134a

Refrigeration Range:

30KW - 580KW

Applications:

Laboratory, scientific research

Magnetic levitation Centrifugal chiller

Temp Range:

5°C - 20°C

Compressor:

Centrifugal

Refrigerant:

R134a

Refrigeration Range:

582KW - 2796KW

Applications:

Food processing, medical, chemical

Air suspension Centrifugal chiller unit

Temp Range:

7°C - 30°C

Compressor:

Centrifugal

Refrigerant:

R134a

Refrigeration Range:

528KW - 5276KW

Applications:

Electronics, semiconductors, manufacturing, energy

Mold Temperature Controllers

Oil Type Mold Temperature Controller

Heating Power:

3 - 72 kW

Heating Medium:

Thermal Oil

Temperature Range:

3°C - 350°C

Accuracy:

±0.1°C

Applications:

Die casting, Rubber molding, High-temp processes

Not sure which system fits your process?

Contact our engineers for a free consultation and selection guide.

Key Components of an Industrial Chiller Unit

Refrigeration compressor

It uses the internationally renowned Japanese Panasonic brand compressor to provide continuous and strong power support for the refrigeration cycle system, with high energy efficiency, low noise, reliability and durability.

Water pump

Equipped with high-quality impellers and energy-saving motors, it can accurately drive the circulation of cooling water, adapt to different flow and pressure requirements, operate stably, and have low energy consumption, ensuring the continuous circulation of water.

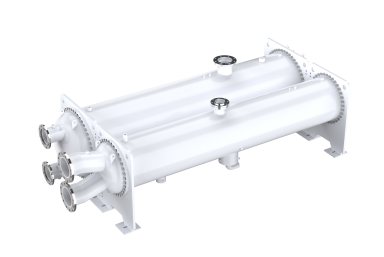

Coil evaporator

It uses high-efficiency heat exchange copper tubes and optimized flow channel design, with high heat exchange efficiency, which can quickly convert refrigeration potential into low-temperature power and accelerate water cooling.

Condenser

It adopts a structure that combines high-efficiency heat exchange fins and copper tubes, and cooperates with the top fan to force heat dissipation, which can quickly condense the gaseous refrigerant into liquid and ensure the recycling of the refrigerant.

Fan

Low noise, high air volume, targeted assistance to condenser heat dissipation, accelerated heat dissipation, and significantly improved condensation efficiency.

Pipeline interface

The nozzles are made of a corrosion-resistant alloy and feature clear functional areas, with the outlet, return, inlet, and drain ports clearly marked. Operational instructions and basic troubleshooting instructions are also provided.

Electric control cabinet

Equipped with high-quality electrical components and modular circuit design, it has high integration and precise control, can quickly respond to temperature adjustment needs, and ensure stable equipment temperature.

Do You Need Clean, Stable Air Supply Too?

Pair your chiller with a professional air compressor solution.

Who We Are

Your Cooling Solution Partner

CE & ISO

Certified Factory

Certified Factory

3,000+ Units

Exported Worldwide

Exported Worldwide

1:1 Technical

Guidance & Design

Guidance & Design

OEM / ODM Available

Full Documentation for Export

What Problems Are You Trying to Solve?

?

Temperature fluctuation affecting your process quality?

?

Equipment overheating and frequent alarms?

?

Unsure whether to choose air-cooled or water-cooled?

?

Tight budget but complex cooling demands?

MINNUO doesn’t just sell chiller units — we deliver complete cooling solutions:

On-demand model selection

Air / water cooling options based on site

1-on-1 technical support

Full specs and piping diagrams

Trusted by 100+ Clients Across Industries

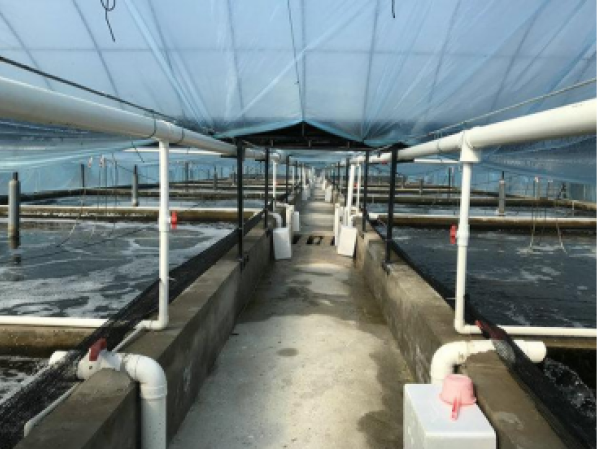

90kw high temperature oil type mold temperature controller

100HP air-cooled chiller with water tank

Chiller workshop display

What Problems Are You Trying to Solve?

1

Cooling Capacity

Indicates how much heat the chiller can remove per hour. Calculated based on equipment heat load:

Q = C × M × ΔT

(Heat capacity × Flow rate × Temp difference).

⚠️ Recommend reserving 10–20% extra capacity for peak loads.

Unit: kW / kcal/h / USRT (1 USRT ≈ 3.517 kW)

Q = C × M × ΔT

(Heat capacity × Flow rate × Temp difference).

⚠️ Recommend reserving 10–20% extra capacity for peak loads.

Unit: kW / kcal/h / USRT (1 USRT ≈ 3.517 kW)

2

Water Flow Rate

Matches cooling capacity. Typically:

1 kW ≈ 3–5 L/min

Ensures effective heat exchange.

Unit: m³/h or L/min

1 kW ≈ 3–5 L/min

Ensures effective heat exchange.

Unit: m³/h or L/min

3

Inlet/Outlet Water

Temperature

Temperature

Affects cooling calculation and heat exchanger sizing.

Common ΔT: 5°C

Smaller ΔT = higher efficiency, but requires larger heat exchanger.

Common ΔT: 5°C

Smaller ΔT = higher efficiency, but requires larger heat exchanger.

4

Cooling Method

Water-cooled: Needs cooling tower, suitable for large capacity or high-temperature environments.

Air-cooled: No water source needed, ideal for dry or mobile setups.

⚠️ Above 35°C, air-cooled efficiency may drop by 8–12%.

Air-cooled: No water source needed, ideal for dry or mobile setups.

⚠️ Above 35°C, air-cooled efficiency may drop by 8–12%.

5

Power Supply

Match voltage and frequency:

Typical: 220V / 380V / 50Hz

Units >200 kW need 3-phase power

Confirm max power capacity on-site.

Typical: 220V / 380V / 50Hz

Units >200 kW need 3-phase power

Confirm max power capacity on-site.

Fill in your application details

— we’ll match the right model within 24 hours.

— we’ll match the right model within 24 hours.

Logistics and delivery guarantee

Export-Ready, Globally Trusted

Export-standard

packaging

packaging

CE, ISO, Form E/C/O

Available

Available

Door-to-door logistics

supported

supported

Online installation &

after-sale guidance

after-sale guidance